Le projet

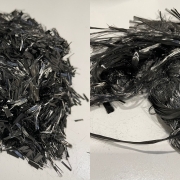

Légers et résistants, les matériaux composites sont utilisés dans la majorité des secteurs industriels. Leur production est en constante augmentation.

Pourtant, la valorisation des déchets liés à cette production massive ne trouve aujourd’hui pas de solution efficace et reste peu explorée.

Face aux enjeux réglementaires et sociétaux, il est urgent de développer des solutions durables en matière de recyclage de ces déchets industriels.

Pour y répondre, Alpha Recyclage Composites se positionne comme un acteur majeur de l’émergence de cette filière.